Cleanroom Manufacturer

Cleanroom Supplier

Modular Cleanroom Manufacturer

CRM - A Professional Cleanroom Manufacturer

CRM is a cleanroom manufacturer dedicated to providing high-standard and tailored cleanroom solutions for industries such as semiconductor, pharmaceutical, medical device, food processing, and biotechnology. With rich engineering experience and technological accumulation, we are capable of providing customers with one-stop, full-process services ranging from the initial consultation, scheme design to construction and acceptance. As a professional cleanroom manufacturer, CRM not only provides high-quality materials and equipment, but also attach great importance to construction management and system integration. We strictly implement quality control and acceptance standards to ensure that every project can be completed as planned and with high quality. Through professional and systematic services, CRM helps enterprises create a safe and reliable clean production environment, improve product quality and create core competitiveness for customers in the field of high-standard manufacturing.

What Is a Cleanroom?

A cleanroom is a professional production space that strictly controls particulate matter, microorganisms, temperature, humidity, pressure and other environmental parameters in the air, aiming to provide a stable and reliable production environment for high-precision and high-standard manufacturing and scientific research activities. Compared with ordinary production environments, cleanroom can significantly reduce the risks of air pollution and microbial contamination, ensure product quality and production safety.

As a professional cleanroom manufacturer, CRM not only offers design, manufacturing and construction services for cleanroom, but also ensure that each cleanroom meets the production requirements of industry standards through full-process engineering management, providing a solid guarantee for the high-quality production of enterprises.

Working Principle of Cleanroom

Cleanroom minimizes the impact of air particles, microorganisms and other pollution sources on the production process through measures such as air cleanliness control, pressure and flow rate management, temperature and humidity regulation, pollution source management, as well as real-time monitoring and verification. High-efficiency filters and fan filter units continuously purify the air, creating a stable airflow and positive pressure environment to prevent external pollution from entering. A reasonable pressure difference and air flow direction design ensure uniform air flow and constant temperature and humidity, which is conducive to product quality and static electricity control. Meanwhile, cleanroom can always maintain a high-cleanliness environment that meets ISO or GMP standards, providing a reliable guarantee for high-standard production.

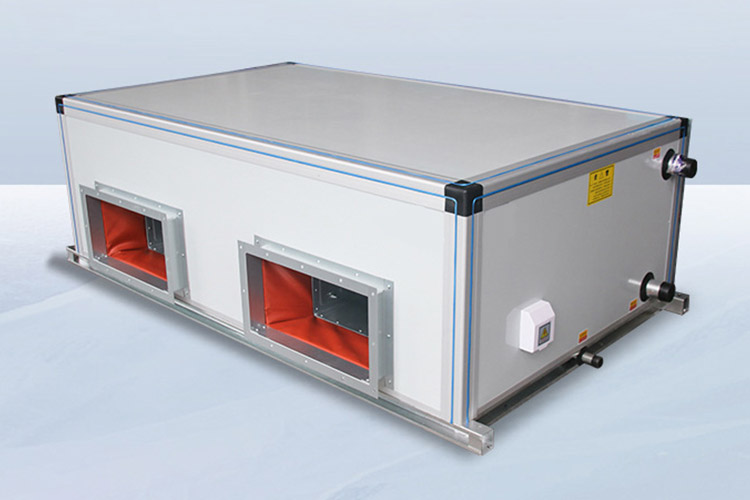

Cleanroom System Components

Cleanroom Classification Standards

Our Services for Cleanroom Manufacturing

Cleanroom Installation Cases

Why Choose Our Cleanroom Manufacturing Services?

Applications of Our Cleanroom